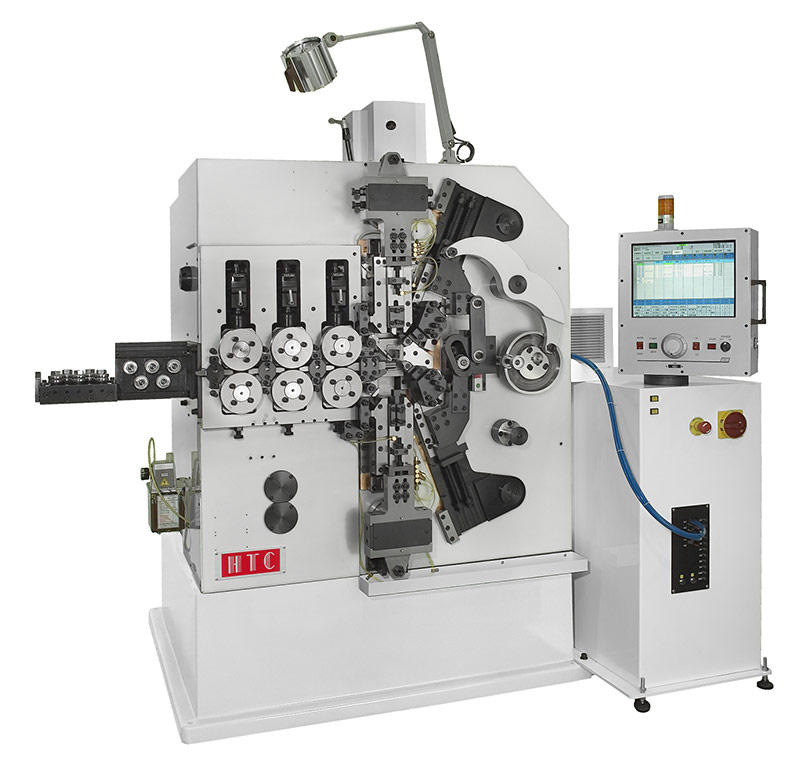

5 Axes Spring Coilers – Standard Features

HTC 5 axes spring coilers provide advanced design technology for precision spring coiling. The five axes series of spring coiling machines are available for wire sizes of 2.2mm up to 8.0mm (.086”-.236”).

CNC CONTROL SYSTEM AND EXCEPTIONAL SOFTWARE DESIGN

- 5 servo motors, industrial computer controlled insuring reliable control.

- Graphic and easy to use software simplifies programming.

- Cam-less operation provides quick and easy setup.

- A micro-pulse hand wheel for easy setup and programming.

- The computer system stops the machine if a programming error exceeds machine setup capabilities.

- On-screen diagnostics shows alarm status and corrective action required.

- Standard spring shapes are pre-programmed for easy setup.

- O.D. control is a standard feature.

- State of the art touch screen control interface for easy operation.

- Programmable air valves provide flexible pneumatic application.

- Security sensor and position sensor included.

- USB data access interface, convenient for program backup and production management.

OPTIMUM MECHANICAL DESIGN

- Advanced design for coiling point system insures easy conversion from right hand to left hand coiling, without coiling point slides replaced.

- Rotating cutoff and straight cutoff capability are both standard features for more flexible application.

- Mandrel in-out movement is programmable which provides setup flexibility.

- Automatic oil pump insures equal lubrication for slides.

- Pneumatic roller clamping system for heavy-duty jobs.

- Roller pressure gages insure repeatable feed roller pressure during changeover.

- Heat exchanger on the electronics chamber keeps controls clean and cool.